A new future opened

up by

ultra-high purity

hydrogen of

Ultra-

High Purity.

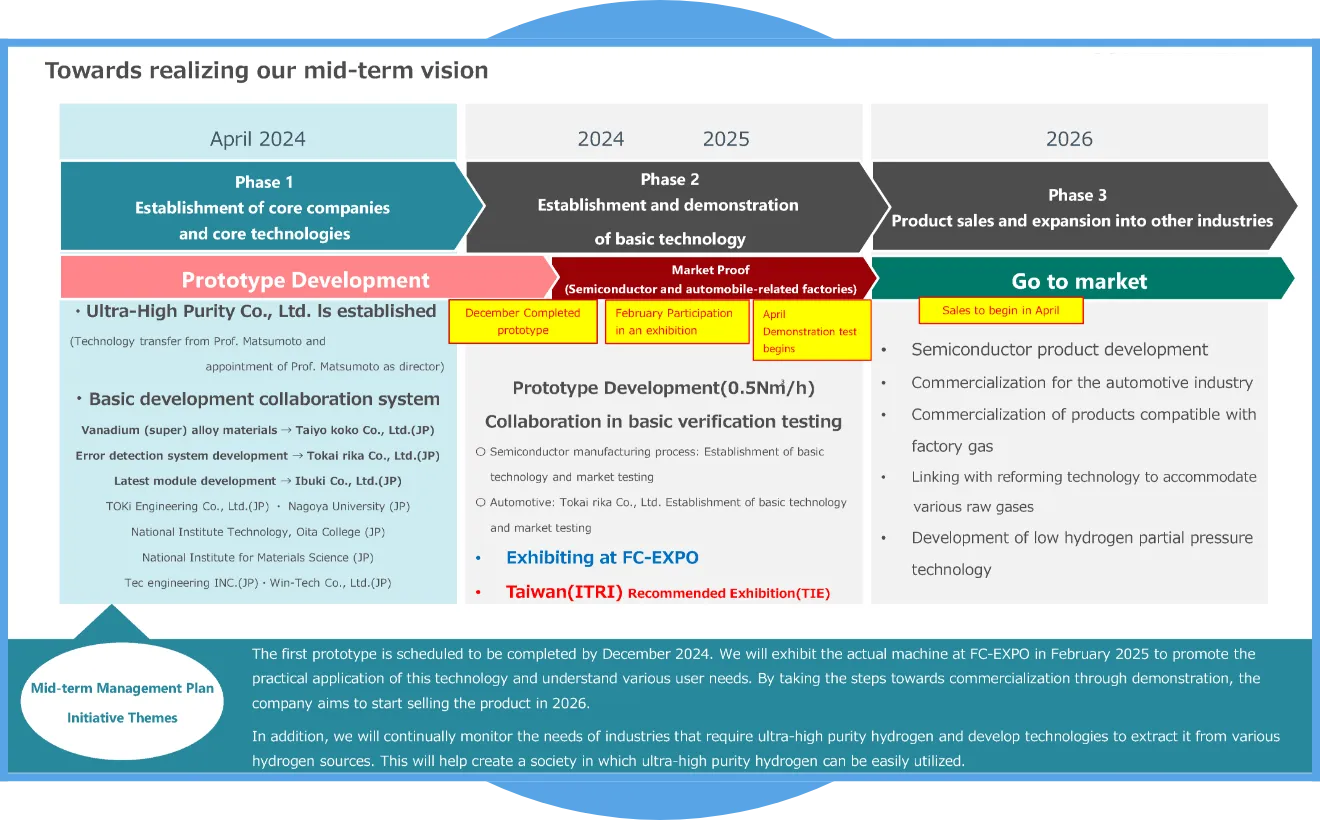

Ultra-high-purity hydrogen has enormous potential to bring next-generation scientific and technological innovations to industries such as semiconductors, medical equipment/devices, space engineering, and automobiles. We believe that our mission is to contribute to enriching people’s lives on the globe by commercializing the technology of Professor Matsumoto who has engaged in a research of hydrogen purification as a long-standing topic. We will continue to promote co-creation with like-minded companies and universities and pass on its results to the society from now on.

TECHNOLOGY

We adopted “VASA-

UHP,” the

cutting-

edge ultra-high purity

hydrogen purification

technology in the

industry.

We adopted “VASA-UHP,” the

cutting-edge ultra-high purity

hydrogen purification

technology in the industry.

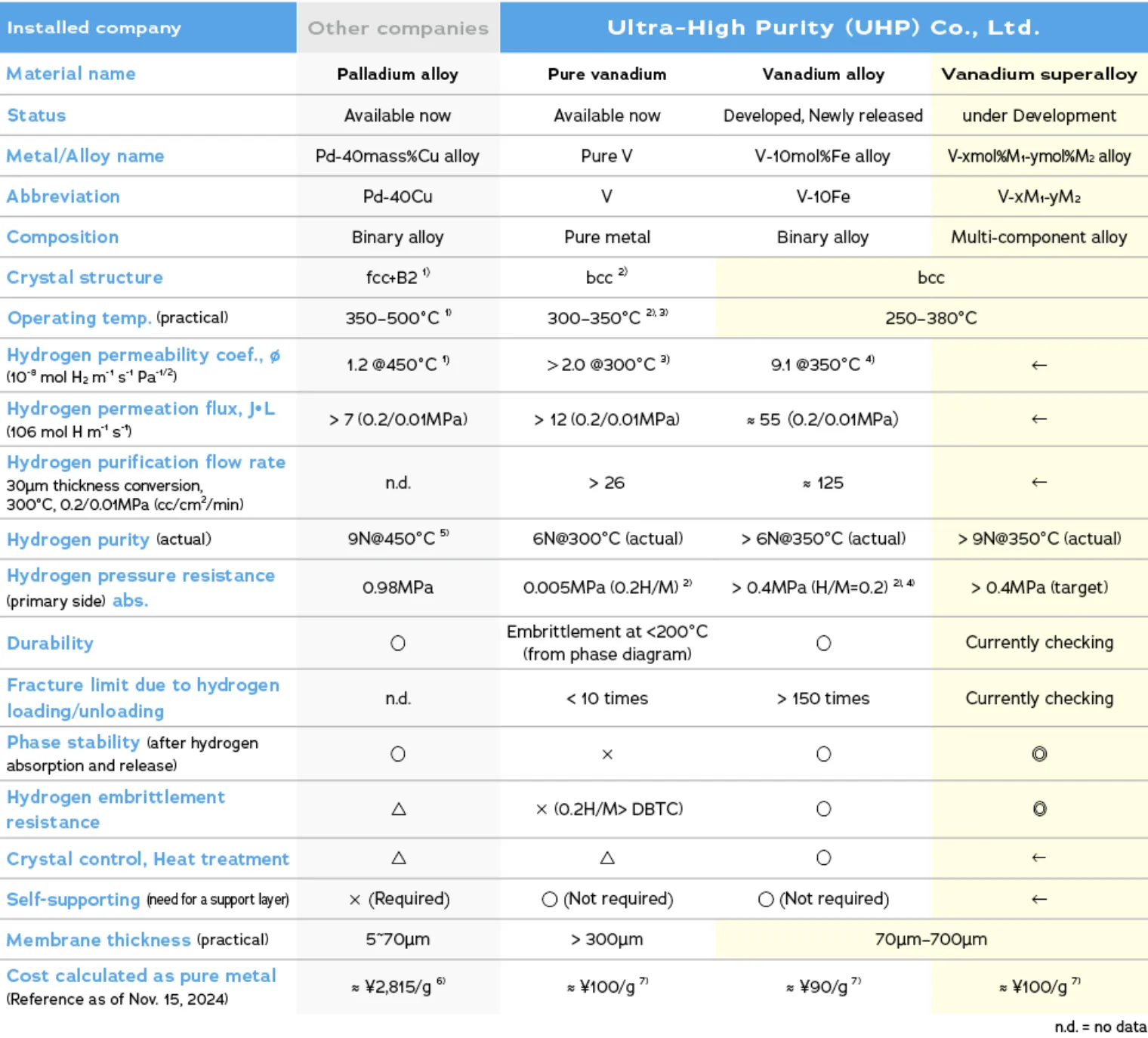

In “VASA-UHP,” which is the ultra-high purity hydrogen purification technology that we engage in developing, we adopted a vanadium metal-based permeable membrane separation method. Its purification efficiency is higher than that of the existing PSA method, and there is no need for large-scale equipment or maintenance efforts for it. Moreover, not only the hydrogen recovery rate but also the durability of membranes and the amount of hydrogen purification are dramatically improved by employing VASA (vanadium superalloy) that combines the best of cutting-edge technologies for permeable membranes, which would have the potential to meet 99.9999% or more of the demand for ultra-high purity. In addition, palladium alloys were traditionally used for permeable membrane separation methods, but energy costs can be significantly reduced by replacing them with inexpensive vanadium superalloys.

Comparison of characteristics and features of various types of hydrogen permeable (separation) metal and alloy membranes

As compared with conventional PSA methods, the permeable membrane separation method can shorten the process, requires less maintenance efforts, and can make its equipment more compact. However, expensive palladium alloys have been used until now. By using vanadium superalloys, we can achieve high-purity purification in addition to reducing costs. Its durability that has been an issue can also be significantly improved.

Reference

- 1) Tatsuya Tuneki et al., Hydrogen Permeability of Palladium-Copper Alloy Membranes, J. Japan Inst. Metals, Vol. 70, No. 8, 2006, pp. 658-661. (in Japanese)

- 2) Asuka Suzuki, Establishment of new paradigm for hydrogen permeable metal membrane and its application to optimal design of alloy membrane for low operative temperature, Ph. D Thesis, Nagoya University, KouNo.11599,2016-09-27, p.42. (in Japanese)

- 3) Yoshihisa Matsumoto, Creation of Hydrogen Separation Membranes by High Pressure Allotropic Microstructure Control and its Application to Low Temperature Operating Membranes with Synergistic Effect, Grants-in-Aid for Scientific Research Report on the Research Achievements; 15H04148, 2018.6.12, p. 3. (in Japanese)

- 4) Hideo Yoshinaga et al., Development of High Capacity Device for Highly-Pure Hydrogen Separation Using Vanadium Alloy Membrane, Materia Japan, Vol. 57, No. 1, 2018, p. 25. (in Japanese)

- 5) S. Adhikari and S. Fernando, Hydrogen Membrane Separation Techniques, Ind. Eng. Chem. Res. 45 (2006) 875-881.

- 6) Simple calculation based on bullion price (selling price) (as of July 23, 2024)

- 7) Estimated value based on interview with Taiyo Koko Co., Ltd. Development Dept. (July 23, 2024) (subject to change)

MATSUMOTO LAB.

Contributing to society

through hydrogen is the

mission of Ultra-High Purity.

A solution to maximize the inherent “ability of vanadium to dissolve and permeate only hydrogen atoms/ions” and to overcome the challenges of improving its durability is “alloys.” UHP will meet current expectations of industrial circles seeking for ultra-high purity premium hydrogen through “VASA-UHP,” which is a unique purification technology using an alloy. We will continue to aim to establish not only refining technologies but also various breakthrough technologies toward carbon neutrality in the future. Please look forward to it.

ABOUT US

Ultra-High Purity is not a company that merely

pursues the success of its own business.

We believe that our mission is to contribute

to the advent of a hydrogen society in the future

where children can live with peace of mind through

the ultra-high purity hydrogen purification technology.

We will envision

a solid future for

a hydrogen society.

COMPANY

PROFILE

- Company name

- Ultra-High Purity Co., Ltd.

-

Head office

location - 1-7-17, Mukaibaru-nishi, Oita 870-0905, Japan

- Establish

ed date - April 11, 2024

- Capital stock

- jpy 29,000,000

- Executive

compositi

on -

CEO, Motohiro Yokoyama

Director, Yoshihisa Matsumoto

Director, Yasutaka Uta

- Business

details -

・Reserch, development, manufacturing and sales of ultra-high purity hydrogen purification modules (VASA

modules)

・Reserch, development, manufacturing and sales of ultra-high purity hydrogen purification equipment

・Patent and licensing business related to ultra-high purity hydrogen

・Joint research on ultra-high purity hydrogen

・Production and sales of ultra-high purity hydrogen

・Hydrogen-related consulting and matching business

・Design, manufacture and sale of gas mixing equipment

・Development and quidance of carbon neutral technologies

・Other hydrogen-related businesses

- Joint developm

ent

company - Taiyo koko Co., Ltd. (JAPAN), Tokai rika Co., Ltd. (JAPAN)

- Partner companie

s - TOKi Engineering Co., Ltd. (JAPAN), Tec enbineering INK. (JAPAN), Win-Tech Co., Ltd. (JAPAN), Ibuki Co., Ltd. (JAPAN)

-

Collabora

tive

Research

Instite - National Institute of Technology, Oita College (JAPAN), Nagoya University (JAPAN)

Access

Domestic

- ・15 minutes by taxi from the west

exit of JR Oita Station - ・30 minutes from Oita I.C. of Oita

Expressway International

International

- ・Taiwan: 4 hours via Fukuoka Airport

- ・Vietnam: 5 hours via Fukuoka

Airport